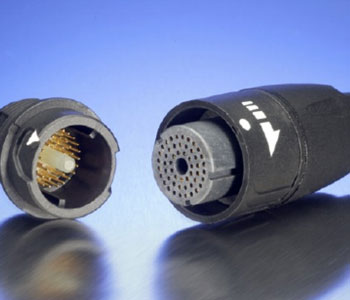

PL-500SM-N Plastic Shell

Ideal for smaller devices and hand-held applications with one (1) to 14 positionsPL-700RG-N Plastic, Medical Disposable

Ideal for disposable or limited-use applications with one (1) to 27 positionsPL-700RG-SC Plastic, Auto-Terminate

Expedite final assembly with automation using reel-to-reel stamped-and-formed contacts in one (1) to seven (7) positionsPL-700SM-B Metal Shell

Perfect when EMI / RFI protection is needed with one (1) to 27 positionsPL-700SM-N Plastic Shell

Ideal when reprocessing of reusable cable assemblies is required with one (1) to 27 positionsPL-900SM-N Plastic Shell

With up to 14 positions, it's perfect for applications requiring higher power handling capabilitiesPL-900RG-N Plastic, Medical Disposable

With up to 52 positions it's perfect for combining connectors to create a simplified interfacePL-1200RG-N Plastic, Medical Disposable

Excellent for higher contact count applications such as EP balloon catheters with up to 78 positionsPL-1300EN-V Plastic Shell, Industrial Ethernet

Pulse-Net® combines the robust latching mechanism Pulse-Lok® is known for with the standard RJ-45 connector

Medical Connector Design Considerations

Configuring the right medical connector for medical devices not only means the solution will work properly, but that it will also help you avoid delays and possible deficiencies in the operation of your medical device. To build an ideal connector for your ideal medical application, enter your Pulse-Lok® number above or click on a series below.

Medical interconnect manufacturing quickly and reliably supplies superior connectors to accommodate medical cable assemblies. As a leading global medical connector supplier, Amphenol Alden's medical interconnect manufacturing provides medical connectors for all types of devices used in hospitals, laboratories, and pharmaceutical facilities.

Medical Connector Capabilities

Connectors can be simple to use and are sometimes compatible with a variety of different medical devices. In some cases, users may connect one unrelated system to another. However, if done incorrectly, this could cause medications or other fluids to be sent through wrong tubing and into incorrect areas of a patient's body. Errors like these are referred to as tubing misconnections or wrong route errors. If you are unsure how to configure a medical connector, Amphenol Alden is here to help. We take the guesswork out of ordering medical device components, cables, or parts, and you will never have to worry about attaching the wrong parts and components - avoiding any misconnections affecting medical devices, entirely.

Contact the Connector Experts

The similar designs, shape, and sizes of medical connectors can sometimes make it difficult to configure them properly. If you’re in need of assistance, contact our team at Amphenol Alden today so you can ensure you’re ordering the right connectors for your medical devices.

Medical Connector Configuration FAQs

Which Medical Connectors are Reusable?

Reusable medical connectors use durable materials and designs to facilitate a longer lifetime than their disposable counterparts. They are able to withstand sterilizations such as autoclaving and hospital-grade chemical wipe down.

Which Medical Connectors are Best for Limited-Use?

The best limited-use connectors make use of cost-effective materials to provide improved value to the OEM. Since they are disposable, they are typically made out of basic medical-grade plastics.

Roughly How Many Uses Should I Get Out of a Disposable Medical Connector?

A disposable medical connector can be designed for exactly the number of uses an OEM desires. Thoughtful material selection can guarantee the right material for the application, and electrical components can be incorporated to disable a connector’s use after a certain number of mating cycles.